How can modern methods of construction improve the construction process?

28 April 2023

Modern methods of construction could improve the construction process – but will everyone get on board? Mike Hayes reports.

In the simplest terms, Modern Methods of Construction (MMC) describes the use of innovative materials, equipment and techniques to build structures.

Its purpose is to reduce project execution time and materials costs, as well as making the building process safer, with a significant amount of what would traditionally be construction work potentially taking place offsite, in a controlled factory environment.

As well as lowering costs through reduced time and waste – and a potentially much reduced workforce – MMC tends to be significantly more sustainable than conventional construction methods, often utilising reduced-CO2 materials and increasing efficiency through the use of advanced technology.

Strange then, that the practice is taking so long to become part of the mainstream operations of European contractors. After all, we have to go back to the 1830s to find the first notable example of the use of MMC principles, when the first modular house was produced.

Slow progress

Is it, once again, a case of continuing to do things the way they’ve always been done, or are there other factors hampering the advance of MMC? Education, for example.

During a workshop on the subject last year, Jamie Hillier of Akerlof, a consultancy specialising in MMC services, explained that it’s not exclusively about off-site solutions, but has much wider significance within construction.

He said, “MMC is a broad term to describe contemporary innovations in construction, including new technologies, such as digital tools and techniques.”

Here we may be seeing one of the reasons MMC has yet to break into the mainstream of construction – a sector that has been notoriously slow on the digital uptake.

The notion of introducing industrial processes to construction also has its sceptics who rightly state that construction projects rarely proceed in a linear fashion. In fact, ‘controlled chaos’ is the way some jobsites are described by project managers.

Photo: Mcavoy

Photo: Mcavoy

In this regard, modular construction would seem to offer obvious benefits, in terms of reducing construction time and making sites safer and more manageable. So how is that done?

Significant time savings using MMC

According to the Modular Building Institute (MBI), Europe’s leading association for the modular construction industry, the time savings predominantly come at this the latter stages of a project, with up to 80% of on-site building activity removed.

Clearly, this is highly advantageous for the construction of buildings in, for example, the educational and healthcare sectors, where it is impossible to simply shut down operations as construction work ramps up.

Currently, even in countries where MMC has been embraced, projects have generally been relatively small in scale.

In the UK, for example, preparation work is currently underway for a €32 million healthcare centre in Newport, Wales.

The contractor on the project is Kier Construction, and Kier called on the services of Premier Modular to produce 14 modular units, totalling 513m2 of temporary space, to minimise disruption, while the new centre is delivered. The modular facility is expected to be in operation until January 2025.

According to Premier Modular, the facilities were delivered and installed in just four weeks, at a cost of €858,000.

Each of the temporary units measured 12x3m, with a structural internal ceiling height of 2.7m.

Premier Modular says the flexible system allows for changing needs of the facility over the course of the construction programme; including the need for additional units.

Speed and security

The UK government has embraced the principles of MMC, committing millions of pounds to accelerate its adoption.

Modular solutions firm Algeco recently benefited from this drive, winning a contract worth up to around €38 million, to supply secure prison units to the Ministry of Justice.

In the face of a growing shortage of secure accommodation for prisoners, the government has initiated a €4.5 billion plan to deliver 20,000 extra places.

In total, Algeco is set to deliver over 500 units this year, including secure sleeping accommodation for approximately 1,000 inmates.

The company developed a Rapid Deployment Cells Project, creating a new design that can be quickly deployed to a variety of sites to help meet the short-term demands of the prison system.

Algeco will deliver enough prison accommodation to house around 1,000 inmates for the UK government (Photo: Algeco)

Algeco will deliver enough prison accommodation to house around 1,000 inmates for the UK government (Photo: Algeco)

James Withey, MD at Algeco offsite, said: “Utilising DfMA [design for manufacture and assembly] and Lean Manufacturing, along with our platform-based approach, will deliver high quality units across these multiple locations.”

This “platform approach” to DfMA carries the acronym P-DfMA and basically signifies the addition of digital systems to the process. Digitally designed components could potentially be used across different types of built assets, allowing for greater industrialisation of the process and, subsequently, lower costs.

The sky’s the limit

While the flexibility and rapid deployment of such units is impressive, it could lead one to suspect modular construction is only viable for single-storey buildings.

In fact, the UK also hosts the world’s tallest modular building, the 135m-tall Ten Degrees twin towers in Croydon, South London.

The 38 and 44-storey towers are not only tall on a modular building scale, they’re simply tall – the tallest buildings in this part of the UK’s capital, in fact.

Each of the buildings’ apartments was factory manufactured off-site by Tide Construction and Vision Modular Systems. The individual ‘pods’ were then simply stacked to create the tower.

Designer HTA says the construction process required up to 67% less energy than a traditional build.

Simon Bayliss, managing partner at HTA Design, said of the project, “Realising a building of this scale and quality at speed required innovation in every aspect of design and construction, from the extensive use of virtual reality and 3D printing for rapid prototyping at planning through to the angled modular façade and large-format glazed terracotta diamonds, which respond to orientation and aspect to create the distinctive architecture.”

Describing the continuity of teamwork, between HTA and the contractors, he said, “working together drove a culture of innovation and continuous improvement, enabling the entire project to be delivered from first concept sketch to handover in just 39 months.

“The modular construction also resulted in a 40% reduction in embodied carbon compared to traditional construction methods, with a significant reduction in waste, and improved quality control to ensure higher performance through operation.”

The 135m-tall Ten Degrees residential tower – built using modern methods of construction – opened in South London in 2021 (Photo: HTA Designs)

The 135m-tall Ten Degrees residential tower – built using modern methods of construction – opened in South London in 2021 (Photo: HTA Designs)

MBI maintains that modular buildings are generally stronger than those built onsite, as each module is engineered to independently withstand being transported and craned onto foundations.

Furthermore, says MBI, the manufacturing plants producing modules have strict quality control protocols, ensuring each element of the building is fabricated to the highest construction standards.

Ultimately, for a modular project to fulfil its sustainability and efficiency promises, it must be built into the project from the very start.

Everyone from the team undertaking the initial design to the fabricators and the teams working on site must understand the MMC principles and execute them.

Standardisation is key

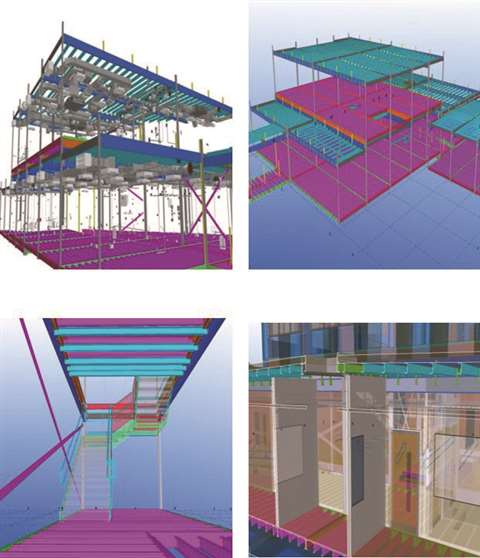

Building information modelling (BIM) is an important piece of software for construction businesses examining modular processes.

BIM is a useful tool from the outset, aiding the design of elements for structures. It can also enable design-to-fabrication workflows and visualise the project in 3D, to ensure accurate execution at the construction phase.

The choice of materials is another key aspect of MMC projects; BIM can help ensure the right materials are selected, both for structural integrity and to ensure reduced execution costs.

One company operating in this space is Bluebeam, which offers software to enable collaborative working.

Bluebeam published a discussion with Jonathan Delcambre, a managing partner at architecture and design firm BKV Group, in which Delcambre said an increase in regulation of prefab parts would encourage more use of the MMC on projects.

“Many companies and fabricators do things their way, so there’s not a tailored process,” he said, adding that modifications required during the construction phase only serve to minimise the benefits of MMC.

Steve Jones, a senior director for Dodge Data & Analytics, agrees. He said, “When designers start to think, ‘Is there a design that would enable prefabrication and or modular construction to occur?’, those delivery methods will boom.”

(Photo: Laing O’Rourke)

(Photo: Laing O’Rourke)

The iconic Olympic Exhibition Centre in London, UK, will receive a €1.1 billion overhaul, with MMC at the heart of the process, says main contractor Laing O’Rourke.

The contractor will be responsible for the redevelopment of the 132-year-old venue’s Grand Hall and the National Hall, as well as the creation of new office space, an arthouse cinema, music venue, theatre and two new hotels.

In total, the ‘Future Olympia’ project, which is jointly owned by Yoo Capital and Deutsche Finance – will cover some 186,000m2.

Laing O’Rourke said early engagement with the project has led all parties to agree a delivery strategy based on Design for Manufacturing and Assembly (DfMA) principles.

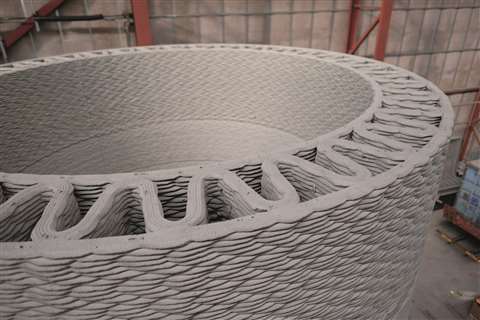

COBOD to ‘print’ wind turbines

There are a number of different methods of construction that conform to MMC principles.

One such is 3D printing technology.

COBOD, a division of formwork specialist Peri, is currently working with General Electric (GE) on a project that aims to produce 3D printed concrete bases for wind turbines.

COBOD is working on economical ways to produce larger structures, able to catch stronger winds.

At the same time, the company is designing a production-ready printer, as well as specially developed materials, with a view to scaling up production.

COBOD believes that, by operating directly on site, it’s printers will be capable of creating pedestals for towers that could then achieve heights of up to 200m, enabling as much as 33% more power from the turbine than is currently generated.

Room for growth in 3D printing

In terms of the scale of growth in the 3D printing market, Philip Knudsen, head of global marketing and communication at COBOD, told CE that the company has researched the global market and believes only 130 buildings have been built using this technology, as of January this year.

(Photo: VBC)

(Photo: VBC)

Leisure operator Parques Reunidos has awarded a €25 million contract to modular building specialist Volumetric Building Companies (VBC), to build a 500-room hotel at its Tropical Islands resort in Berlin, Germany.

Within the contract, VBC will deliver and install the hotel room modules, complete with furniture, for the five-storey hotel building.

VBC will fabricate a range of guest room types, including two- and four-bedroom family suites; double, accessible and 36m2 deluxe rooms.

The furniture – including beds, shelving, bathroom vanity units and wood and glass partitions – will be manufactured in VBC’s factory in Poland.

The completed room modules will be installed on a concrete podium which accommodates the public areas and guest amenities.

According to VBC, the guest room modules will arrive on site this summer and will be installed in just two months.

The hotel is due to open early 2024.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM