Helicopter assists repairs to underground ventilation shaft

05 October 2021

Helicopter hovering above the ventilation shaft of Cowburn Tunnel in the Peak District. ©Network Rail

Helicopter hovering above the ventilation shaft of Cowburn Tunnel in the Peak District. ©Network Rail

A helicopter has been used to assist in essential repair works to what is said to be one of the deepest railway ventilation shafts in the UK.

According to Network Rail, the helicopter - an uncommon sight when it comes to projects involving tunnels - was used to lower materials into position for works to the Cowburn Tunnel in the Peak District.

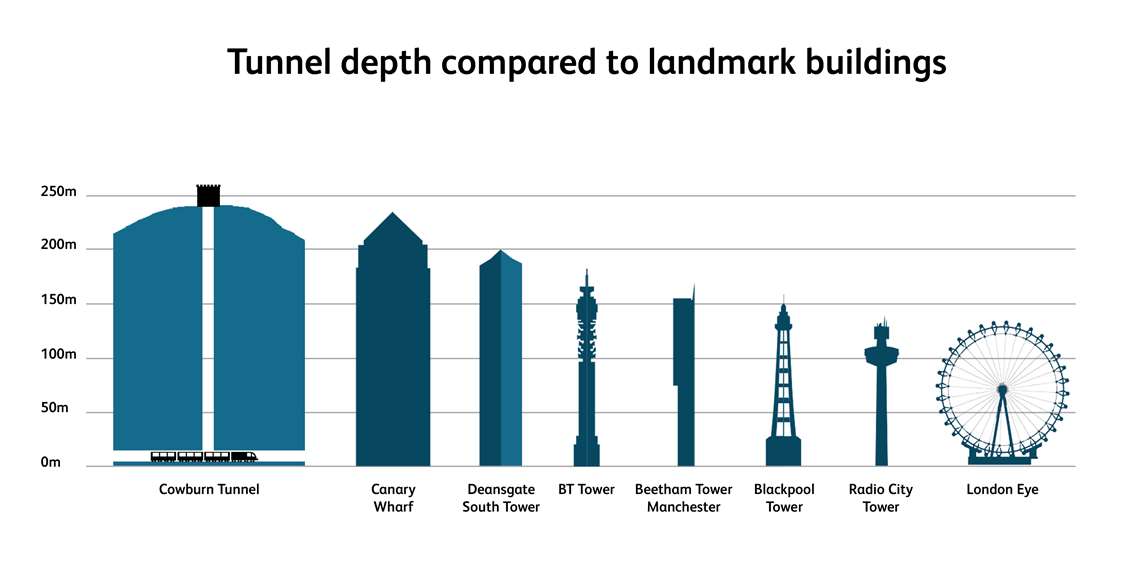

The 130-year-old ventilation shaft to Cowburn Tunnel measures 241 metres long and is vertically dug into a hillside. According to Network Rail, if it were a building, it would be taller than London’s Canary Wharf.

During the course of its life the railway tunnel’s ventilation shaft has “inadvertently acted like a huge drainpipe”. Repairs works to the shaft were undertaken to rectify flooding issues that affect the running of train services along the track beneath it.

Cowburn Tunnel size comparison graphic ©Network Rail

Cowburn Tunnel size comparison graphic ©Network Rail

Network Rail said, “When rain falls on the land above it seeps through the soil before making its way through the ventilation shaft’s brickwork, cascading like a massive shower head into the tunnel and tracks below.”

“Because of its remote location, helicopter pilots were drafted in to transport vital materials and components for work on the tunnel’s ventilation shaft.”

Originally built in 1894, it took 102 men working eight-hour shifts around the clock for two years to complete the ventilation shaft.

The shaft opens into a 10-metre-high chamber to the side of the railway track, “known as ‘the Cathedral’ because of its pristine stonework”.

The helicopter airlifts materials into position onsite ©Network Rail

Dennis McGonnell, Works Delivery Manager at Network Rail, said, “It’s a huge privilege to keep heritage structures like Cowburn Tunnel in good condition for rail passengers and freight and it’s amazing to see up close the quality of the Victorians’ workmanship.

“We work on a lot of structures in remote locations but working in a tunnel this deep and using helicopters to get materials to site is rare.

“It makes you realise what an amazing feat of engineering building this tunnel and ventilation shaft was all that time ago without the modern machinery we have today.”

Works to the tunnel involved the installation of a system of drainage pipes that collect and divert water into an underground drainage network.

A temporary lift platform and a custom-built cradle were also installed, to enable engineers to install the ventilation shaft’s new pipes and water collecting devices.

Cradle lowering into Cowburn Tunnel ventilation shaft ©Network Rail

Cradle lowering into Cowburn Tunnel ventilation shaft ©Network Rail

According to Network Rail, this meant that disruption to the railway line’s passenger and freight services could be avoided, as trains could still run in the tunnel below.

Despite only being able to carry out track-level improvements to the tunnel’s drainage on Saturday nights when services weren’t running, the project was completed as scheduled in less than two months.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM